Our Services

Future Green Solutions

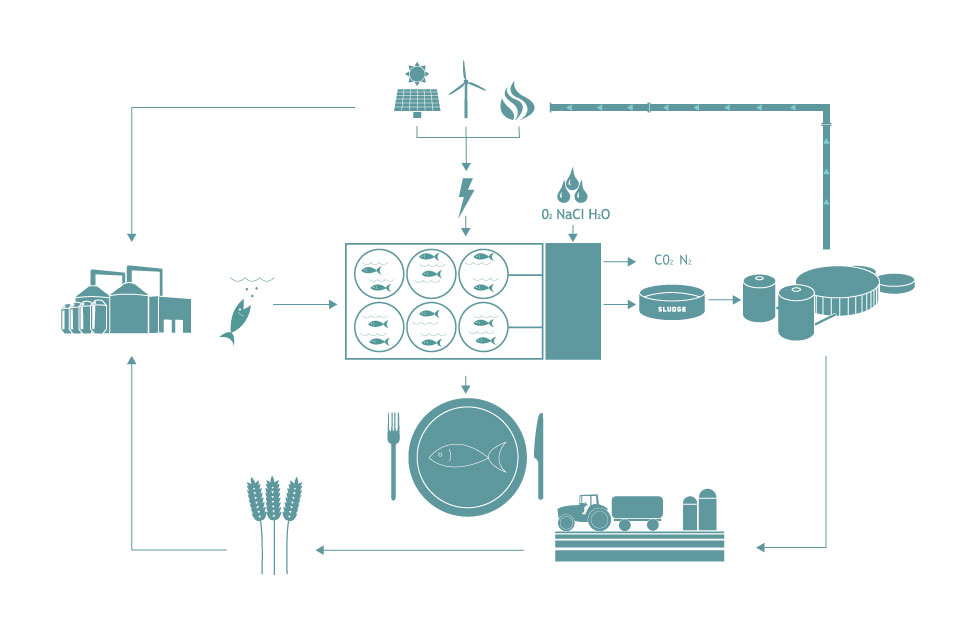

At RAS-CON we believe it is crucial to know the voice of the customer. One of our time most discussed issues is our caring for the nature whether it is carbon footprint, production emissions, medicine usage or global warming – the topic has never been more relevant. The end customers demand a conscious product they can eat and feel good about. Fish production is a part of the surrounding environment, and we see that as a beneficial possibility. We have made our projections of the Future Green Solution within RAS farming.

Fresh delicious fish

The product goal is focused on high quality meat, tender and full of taste … healthy fish without medication ready for processing and to be sold to the end customers. The cost price of salmon must go down to enable higher per persona consumption and to lower the intake of red meat. For many people salmon is luxury, and lower prices would yield a broader range of customers.

Fish tank

The fish swims in designated tanks. They get their muscles trained by the incoming and oxygen rich flow of water. The fish are daily feed and gain weight. Fish produce feces and carbon dioxide which is carried out with the water. Up to several times pr. hour the water in the tanks has been recycled and cleaned. Like land living animals, fish produces carbon dioxide and nitrogen as part of their metabolic process. This must be removed from the water, because too high levels will kill the fish.

RAS

The gravity driven flow pipe system leads the waste from fish tanks to the water treatment system. Simply explained, this system removes and/or breaks down the organic material and nitrogen by use of mechanical filtration (filters), aerobe and anaerobe biological filters that captures and / or degrades organic material and nitrogen.

Ozone is used in small doses to degrade fine and /or dissolved organics, to increase transparency in the water and to reduce bacteria levels. The degassing system makes sure to aerate and strip the water from carbon dioxide and nitrogen among others. Phosphor, dissolved organics and heavy metals that may occur, is captured in the de-phosphorus system. Once cleaned, the water is pumped back to the tanks, and before entering the water it is lead through an oxygen cone to ensure rich levels of oxygen in the clean water.

Sludge

The sludge separated from the water is stored in tanks to be picked up occasionally from for example a biogas plant.

Energy

Producing fish on land consumes electricity and heat. There are many ways to get the energy. You can buy the energy traditionally from local suppliers or you can buy certified green energy and use it to profile yourself. Whether it is wind, solar, water or bio, the possibilities are here to be used. The effluences from your plant can be used to power the pumps – that’s green!

Farming – agriculture

The leftover biomass from the biogas station can be used as manure. The biomass maintains its fertilizing abilities after the rottening process. The farmer has a great part to play when it comes to feed, since the future demand on plant based proteins will increase.

Feed

The manufacturers of feed are becoming more and more conscious about what they put into the feed. The protein and oil source from fish is decreasing, and the level of plant based protein and oils in fish feed is increasing. Being able to farm nearly all the components going into the fishfeed, the feed manufacturers minimize the environmental impacts and helps the local economy with the help of RAS. The amount of fish going into the feed is steadily decreasing and being substituted with soy based proteins – a great step towards a more sustainable production of fish. By using the correct ingredients, it is also possible to brand the fish as ecological.

Additives

To make the RAS work on a daily basis a few components are needed: NaCl (salt), O₂ (Oxygen), H₂O (Water) and CaCO₃ (Chalk), as well as small amounts of C₂H₅OH (Methanol) and FeCl₃ (Iron chloride).